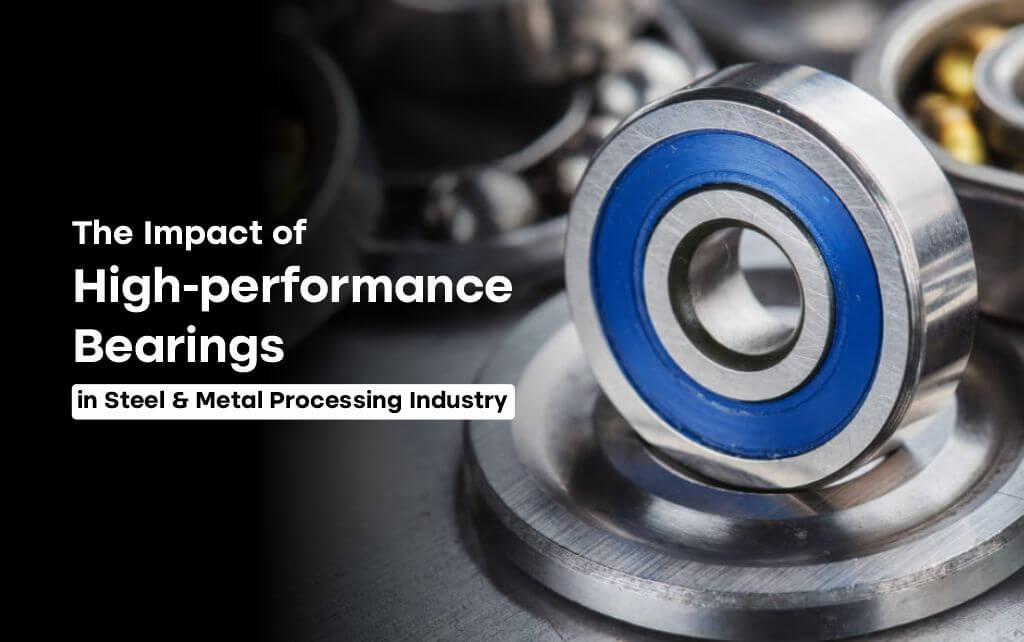

In the modern industrial period, equipment and machines must be accurate in their function to benefit manufacturing industries. Actually, the bearing is one of the smaller elements that play a vital role in industrial applications. Bearing finds its application in the steel and metal processing industry, where huge machinery and equipment are used under considerably higher stress and strain. Heat-resistant bearings are crucial to raising production rates, lowering maintenance expenses, and increasing machines’ life spans. This blog will focus on using high-performance bearings, especially in the steel and metal industries, while analyzing their performance.

What Are High-Performance Bearings?

Bearing minimizes load movement and ensures a smooth division of loads when moving parts are in contact. Specialized bearings are designed to ensure that they perform under given conditions, such as high load and high speed, and are likely to work under high temperatures. These bearings are developed from high-quality raw materials and highly accurate manufacturing techniques to make them long-lasting, accurate, and reliable.

For example, in steel and metal processing, high-performance bearings are used in rolling mills, crushers, and conveyors, among others. These bearings ensure that the machinery efficiently moves at this speed with little or no frequent breakdowns. High-performance bearings have been well suited for such industries due to the challenging working conditions they offer and as such, are ideal for manufacturers seeking ways to enhance production.

Why Do High-Performance Bearings Matter in Steel & Metal Processing?

In the steel and metal processing industry, various types of machinery perform services like rolling, stamping, forging, and machining, among others. These processes put a lot of stress on equipment; therefore, parts of the equipment must be substantial and optimized. High-performance bearings solve these issues in the following ways, which influence the performance of machinery.

1. Increased Efficiency and Productivity

High-performance bearings is one of the essential units that have considerable benefits in enhancing efficiency and production in steel and metal processing industries. These bearings are used to meet the firm’s need to minimize friction, leading to enhanced movement within the members of a given machine. Therefore, there is less interference from these machines with operations, which leads to high processing speed.

Relay-on usage areas such as rolling mills where metal foils are passed through rollers and high-performance bearings enable rollers to rotate optimally. This results in faster processing time so manufacturers can meet the set production goals.

2. Extended Equipment Lifespan

High-performance bearings are made to endure harsh environments. They are typically made of high-carbon steel and can tolerate high temperatures, loads, and abrasive environments in steel and metal processes. This minimizes the need for replacement, thus prolonging the operational span of the machinery tremendously.

For instance, in the steel rolling mill industry, high-end bearings create the capacity to prolong the use of rolling mill machinery in the factories. This reduces the time and costs of repairing and replacing the affected products.

3. Reduced Downtime and Maintenance Costs

In circumstances where the breakdown of equipment and devices results in extensive losses, high-performance bearings would prove economical in terms of maintenance. It has been observed that these bearings are designed to last longer; thus, they are likely to be used for a long time without requiring regular re-lubrication. This is particularly useful for companies operating in the steel and metal processing industry as the machinery runs or works around the clock.

High-quality bearings ensure minimum maintenance requirements, and since possible breakdowns are avoided, scheduling for maintenance is easily done, reducing downtime. Thus, it is possible to maintain a steady output and increase general business profitability.

4. Enhanced Load-Bearing Capacity

A lot of the steel and metal processing equipment is used on heavy loads; thus, the bearings are bound to wear out with time. These high loads are usually handled by high-performance bearings that help to ensure continual and smooth operations of the concerned machinery no matter the pressure exerted on it. This ability is especially valuable in crushers where mass volume is subject to processing and in presses to form metal sheets under pressure.

These higher load ratings suggest that high-performance bearings can operate under these conditions without any limitations while not affecting the performance of the machinery. This results in increased productivity and reduced chances of equipment breakdown.

5. Improved Precision and Accuracy

High precision is as important as ever in steel and metal processing. It is also evident that slight variations within the manufacturing process can create defective products. Bearing is essential to reduce vibration, which can negatively affect the smooth operation of the mechanism, and to decrease friction between moving components. This leads to more accurate processing, especially in operations such as computer numerical control (CNC) machining, which requires high accuracy.

When moving products, high-performance bearings can generally control extra dimensions and surface patterns, resulting in improved product quality.

The Future of High-Performance Bearings in Steel & Metal Processing

Based on the current trends in technological developments, it can be predicted that there will be increased use of high-performance bearings in the steel and metal processing industry. The manufacturing industry needs to enhance production rates by lowering maintenance costs to manageable levels. High-performance bearings with improved load-bearing capacity, lifespan, and accuracy will remain for continued use in enabling such businesses to realize their goals.

Further development in the bearing material may be anticipated to be even better than what it is known today, namely the hybrid bearings. These innovations also enable the development of better equipment for further processing of steel and metals to allow the manufacturers in the market to deal with tough competition.

S. GOEL BEARING & CO.: Your Trusted Partner in High-Performance Bearings

S. GOEL BEARING & CO. is a specialized bearing importer of a wide range of high-end bearings for industrial applications, particularly for steel and metal industries. Being associated with the manufacturing industry for many years and having an insight into the problems faced by the manufacturers, S. GOEL BEARING & CO. supplies all varieties of bearings to its customers.

The company deals with bearings that are made to withstand high performance while simultaneously being highly durable, precise, and reliable. The rolling mill bearings, crushers, or any other equipment for processing may be different, but we have solutions that improve your operations and reduce maintenance frequency.

Having a competitive advantage based on quality and customer satisfaction, S. GOEL BEARING & CO. remains one of the leading and reputable suppliers in the bearing industry.

Final Words

In conclusion, high-performance bearings are essential for steel and metal processing industries. These advantages include enhanced productivity, increased equipment usage, reduced time off-time, and improved accuracy. If the manufacturer gets the right bearings for their equipment, they not only enhance the performance of their production line’s flow but also the maintenance’s lifetime cost.

Companies like S. GOEL BEARING & CO. supply good quality imported bearings that are quite necessary for the production process in steel and metal processing industries and other industries that do not compromise on quality. So, it is always wise to opt for high-performance bearings if performance and durability are significant to the business.