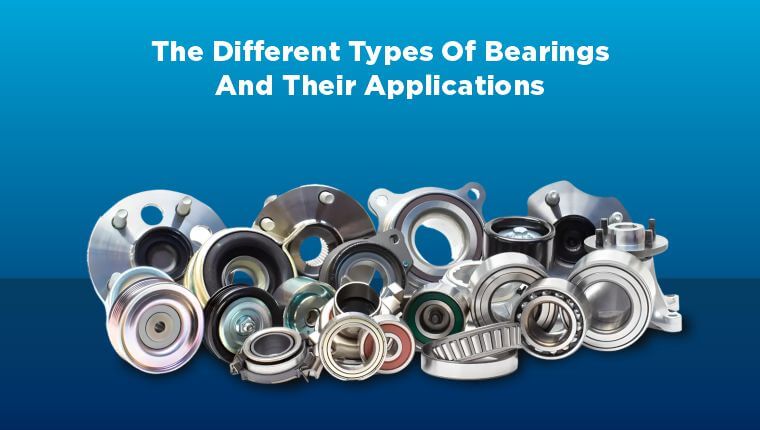

Bearings hold an important place in a lot of machinery and household items. They are necessary for reducing friction and allowing smooth motion in a wide variety of machinery and gadgets. Recognizing different types of bearings and their applications will help you understand the finest solution for your needs, whether you are working with everyday appliances or High-tech industrial systems. The usage of bearings is necessary for the accurate operation and longevity of any machinery. The blog gives you a detailed explanation of various types of bearings and how their application contributes to optimal performance across industries.

Explore The World Of Bearings: Varieties And Their Uses

Various types of bearings are used for different applications. These bearing helps in transferring load, protecting parts, and limiting movement:

Ball Bearings

By their names, you can guess that these are a type of rolling element bearings. These bearings have balls that preserve the separation between the moving parts. Their compact design is made by using two ring-shaped tracks that have the same width but differ in diameter.

They reduce friction between two surfaces, allowing smooth rotation. If you buy a high-quality bearing, you will notice that the design of ball bearings minimizes wear and tear. It makes ball bearing a perfect solution for machinery that needs high-speed application.

Classification of Ball Bearings

- Deep Groove Ball Bearings – Many bearing importers in India claim that these bearings are the most common ones. They have a simple structure. It contains a ball element, an inner and outer race, and a cage that divides the balls and keeps them uniformly distributed. These bearings can effectively manage both radial and axial loads and are also cost-effective because they create less friction. The reduced friction lowers the operating temperature, reducing energy costs.

- Angular Contact Ball Bearings – Annular bearings are a type if rolling element bearings which can handle both radial and axial loads. These are considered one of the best bearings for heavy machinery. An angular contact ball bearing can handle axial load in both directions. Their unique feature is that it can support higher speed while also maintaining stability under heavy loads. These are mostly used with heavy construction equipment, transmissions, and machine tools.

- Thrust Ball bearings – These bearings are designed to handle axial loads but cannot perform radial loads. These bearings contain two races and a set of balls. This design helps them in handling heavy axial forces effectively. These bearings are majorly used in household appliances, fans, Pumps, and agricultural machinery.

- Self-Aligning Ball Bearings – These bearings are special types of bearings because they are designed to manage the misalignment between the shaft and housing. These are mostly used in machinery where perfect alignment is hard to achieve. These bearings also excel in handling radial loads.

Roller Bearings

Roller bearings are completely different from ball bearings, where the ball bearings use balls; roller bearings use cylindrical rollers. Its design reduces friction between two moving parts of the machinery.

The roller bearings distribute the loads over a larger surface area, which makes them an ideal choice for heavy-duty applications. The advantage of roller bearings is that they can handle higher radial loads than ball bearings. This is also one of the reasons that these bearings are used widely in different industries.

Variety of Roller Bearings

- Cylindrical Roller bearings – Cylindrical roller bearings are an advanced type of rolling-element bearing which comprises cylindrical shaped roller to support heavy loads. These rollers encourage lubricant film formation, which results in lower friction. These bearings are mostly used in heavy machinery. The installment of these bearings is simple and can be done without much assistance. Additionally, their slim design makes them a space-saver.

- Tapered Roller Bearings – Just like their name suggests, these bearings have a tapered design. These bearings are a combination of two rings an inner ring known as cone and an outer ring called cup. A set of tapered roller is arranged between both the rings. Tapered roller can manage both loads – radial and axial. Their design makes them sufficient enough to handle heavy weights while also maintaining stability. These characteristics make them a perfect fit to use while operating heavy equipment.

- Spherical Roller Bearings – The spherical roller have two rows of symmetrical spherical rollers. These rows are set between an inner ring and an outer ring. There’s a cage that holds both the rollers in place. Their unique feature is that these bearings are great for handling misalignments. They get their name because of this spherical shape, which makes them a suitable option to use where shaft alignment is hard to get. They are great for the equipment and machinery that works in challenging conditions, such as wind turbines and construction machinery.

- Tapered Roller Thrust Bearings – These bearings have a tapered roller that is arranged between a cone-shaped inner race and a flat outer race. Their versatile application makes them suitable for various industries, such as gearboxes, industrial machinery, wheel hubs, and many more.

- Spherical Roller Thrust Bearings – These rollers have got their name due to their spherical shape. The spherical shape helps them align with the raceways. These bearings can easily handle heavy axial weight. These can also work well with some radial loads. These are designed in a way that can be effective in managing a misalignment. These are ideal to use with power machinery and power generation machinery.

Unlock Excellence In Bearing Solutions: Contact S. Goel Bearing And Co. For Your Bearings Needs

To choose the right bearing for your needs it is essential to know their applications and types. From ball bearings that can efficiently handle high-speed applications to roller bearings that are exceptional in handling heavier loads, the blog explained the applications of these bearings. This blog will help you in making a wise choice when selecting a bearing. The right bearing impacts the performance, efficiency, and longevity of equipment. If you are involved in manufacturing or maintenance and want to know the most suitable bearing option for your industry, the bearing specialist are here to help.

We, S. Goel Bearing and Co. have been a trusted bearing importers for different industries. We are one of the top suppliers of bearings. The bearings are made after a thoughtful consideration of your required machinery. From different ball bearings to various kinds of roller bearings, we meet the demands of every consumer. You just need to tell us the machinery you work in and our expert team will find the most suitable bearing for you. Check our official website to get the best quality bearings, and connect with us to discuss your requirements.